ESA GRATING

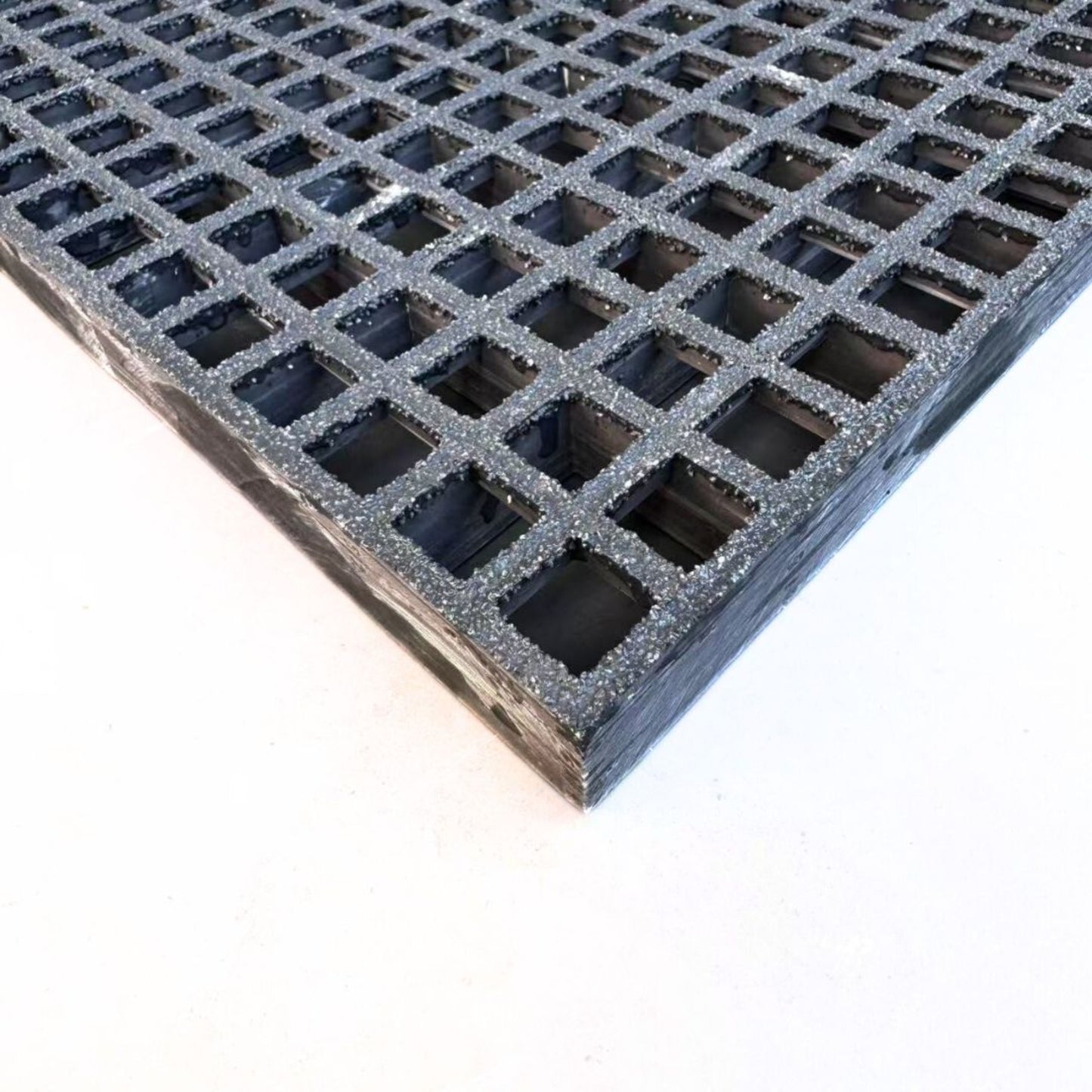

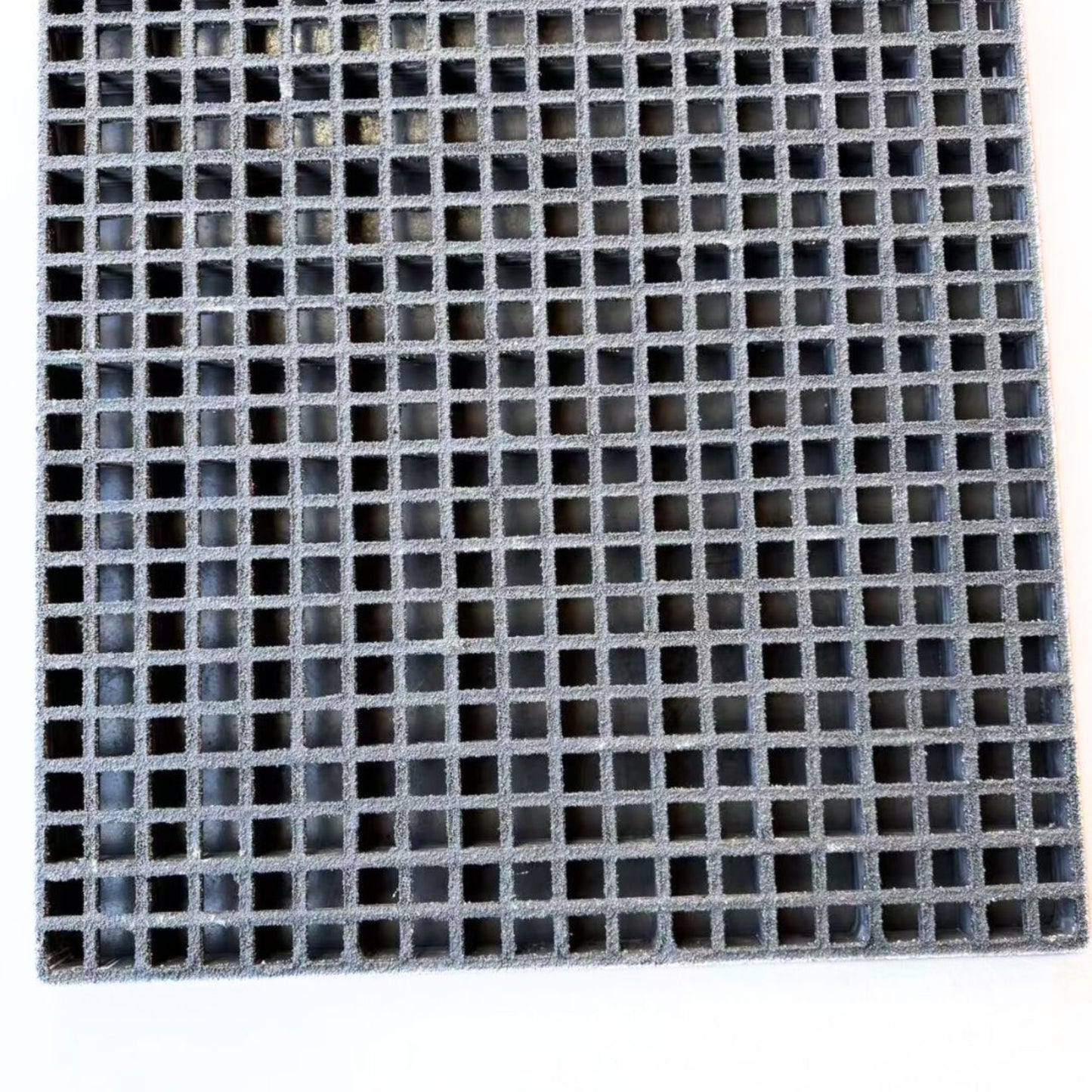

FRP Anti-Slip Grating 25x25mm Mini Mesh 25mm Thick

FRP Anti-Slip Grating 25x25mm Mini Mesh 25mm Thick

Low stock: 8 left

Couldn't load pickup availability

A forklift is required for delivery if the panel exceeds 30 kg. Otherwise, the shipment will be sent to your nearest depot for collection.

Product Overview

ESA GRATING premium FRP (Fibreglass Reinforced Plastic) grating with 25x25mm mini mesh design, delivering exceptional anti-slip performance and corrosion resistance. Ideal for chemical plants, wastewater treatment facilities, offshore platforms, docks, and industrial environments across Australia.

Key Benefits

- Superior Anti-Slip Performance - Grit surface finish provides excellent traction even in wet conditions

- Corrosion Resistant - Fibreglass reinforced plastic construction resists chemical corrosion for extended service life

- Lightweight & Strong - 75% lighter than traditional steel grating while maintaining structural integrity, easy to install and transport

- Maintenance-Free - No rust, no corrosion, no need for regular maintenance or repainting

- Safety Compliant - Meets Australian industrial safety standards for demanding work environments

Product Specifications

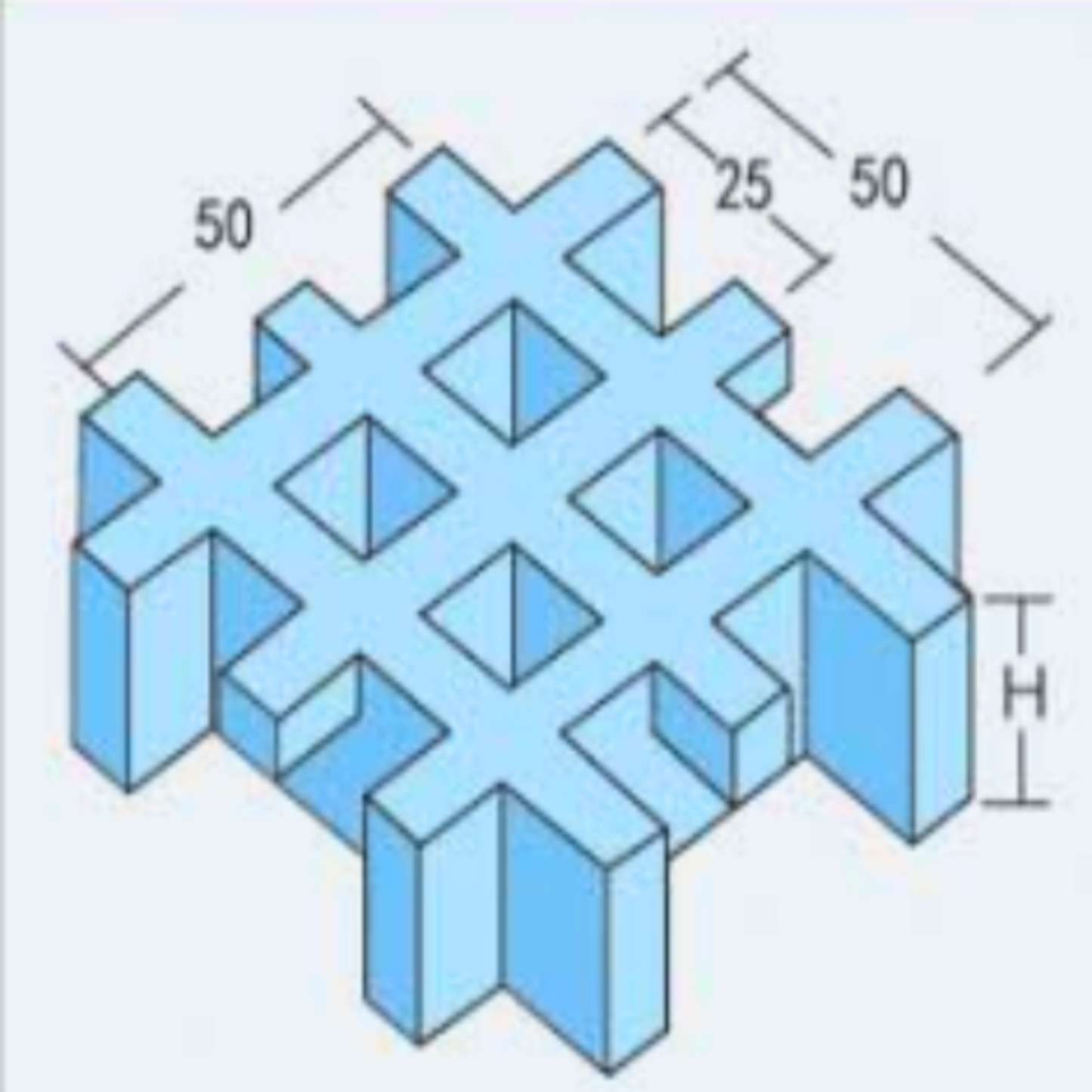

| Dimensions | 1220mm x 4017mm |

| Thickness | 25mm |

| Mesh Size | 25mm x 25mm (Mini Mesh) |

| Colour | Dark Grey |

| Surface Finish | Anti-Slip Grit Top |

| Material | Fibreglass Reinforced Plastic (FRP) |

| Weight | Approx. 70kg per panel |

| Load Capacity | Suitable for industrial pedestrian walkways and light equipment areas |

| Fire Rating | Self-extinguishing, low flame spread |

Applications

- Chemical plant operating platforms and walkways

- Wastewater treatment facilities

- Offshore platforms and marine docks

- Food processing plant wash-down areas

- Industrial flooring in corrosive environments

- Electroplating workshops and pickling areas

- Mining and mineral processing facilities

Installation

FRP grating panels are easy to install using bolt-down or clip-fix methods. The lightweight design reduces structural support requirements, lowering overall project costs. Professional installation recommended to ensure safety and compliance.

Maintenance

FRP grating requires virtually no maintenance. Routine cleaning with water is sufficient. No painting or rust treatment needed, significantly reducing long-term maintenance costs.

Why Choose FRP Over Steel?

FRP grating outperforms traditional steel grating in corrosive environments. It won't rust, corrode, or deteriorate when exposed to chemicals, saltwater, or harsh weather conditions. The non-conductive properties also make it safer in electrical environments.

25x25mm mini mesh applications

-

Garden Floor

-

Sheep Shearing Shed

-

Ramp

Cut To Size

Whether you're working on a small DIY project or a commercial project, we're proud to offer cut-to-size sheets here in the heart of Melbourne.

We use the circular saw or grinder with diamond blade.

Frequently Asked Questions

Does FRP crack easily?

FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

What are the two main components of FRP?

FRP composite materials are usually based on two major components; fibers and polymer matrix. The stiffness and strength of composite materials are controlled by fibers, while the role of matrix is to transfer load and provide protection against environmental elements.

Is FRP bad for the Environment?

Plastic typically has a bad reputation when it comes to the environment and suffers from the image of cheap limitation, compared to other materials. But when used correctly, FRP is a good option that is much more sustainable than aluminium, steel or timber.

What is the life expectancy of FRP grating?

FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years.