ESA GRATING

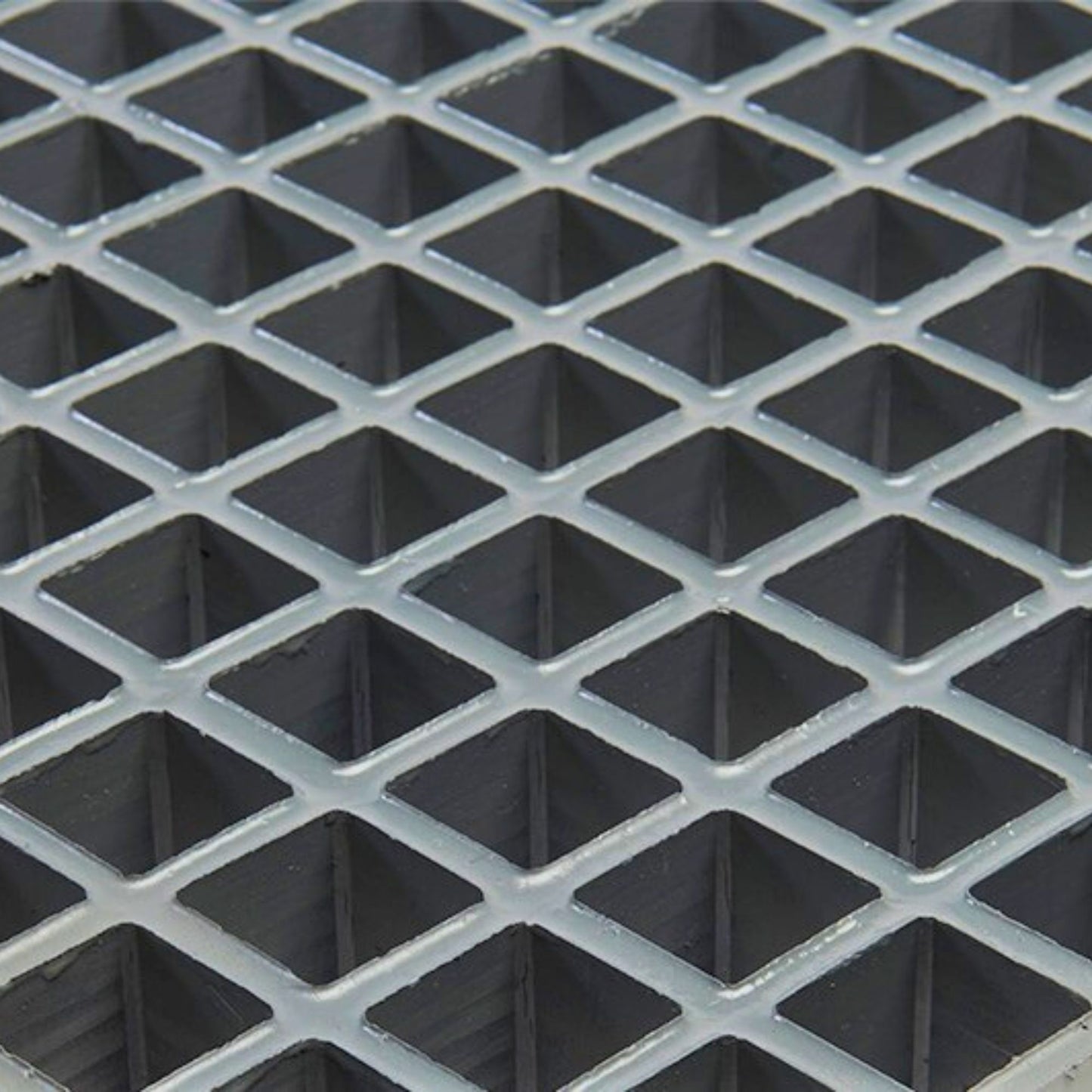

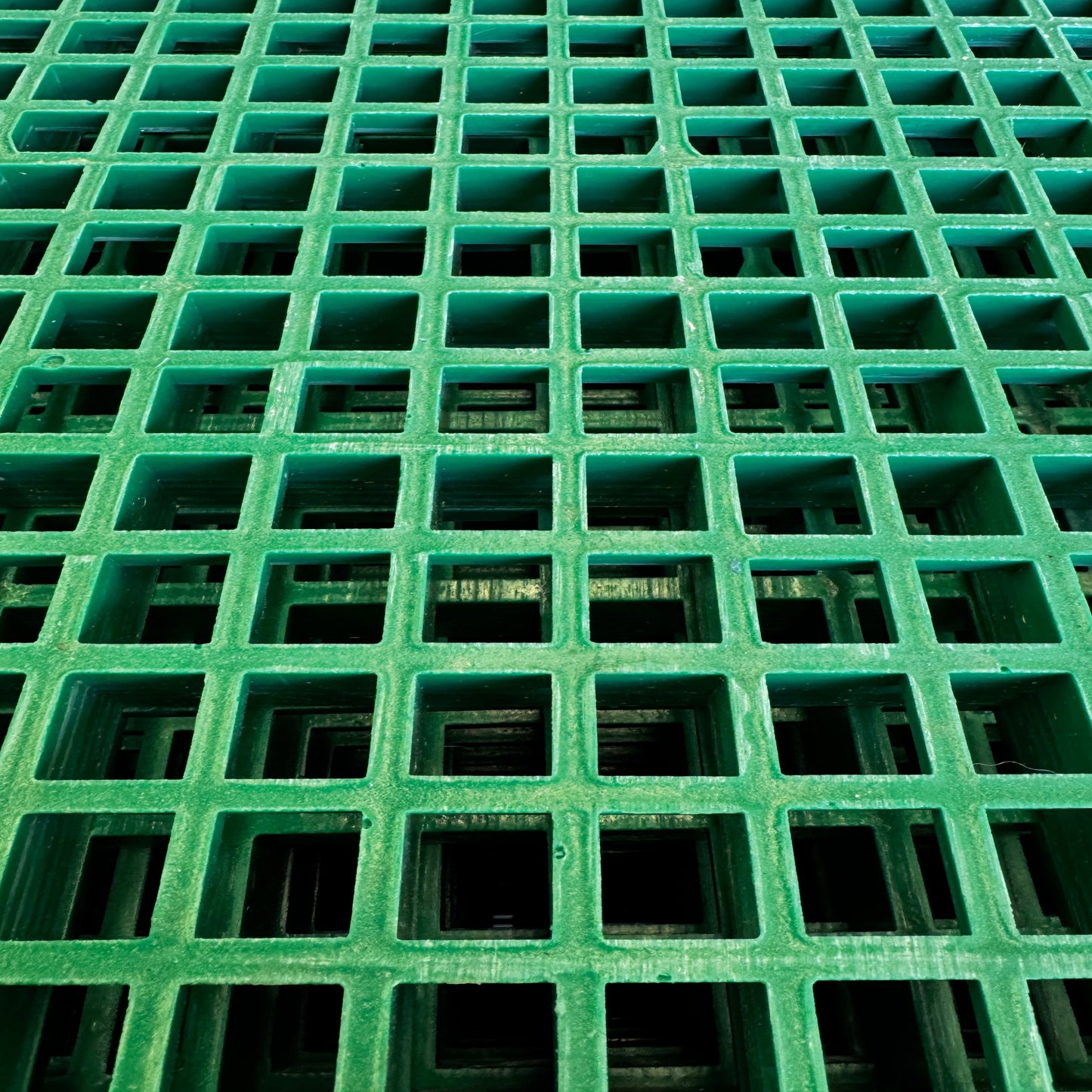

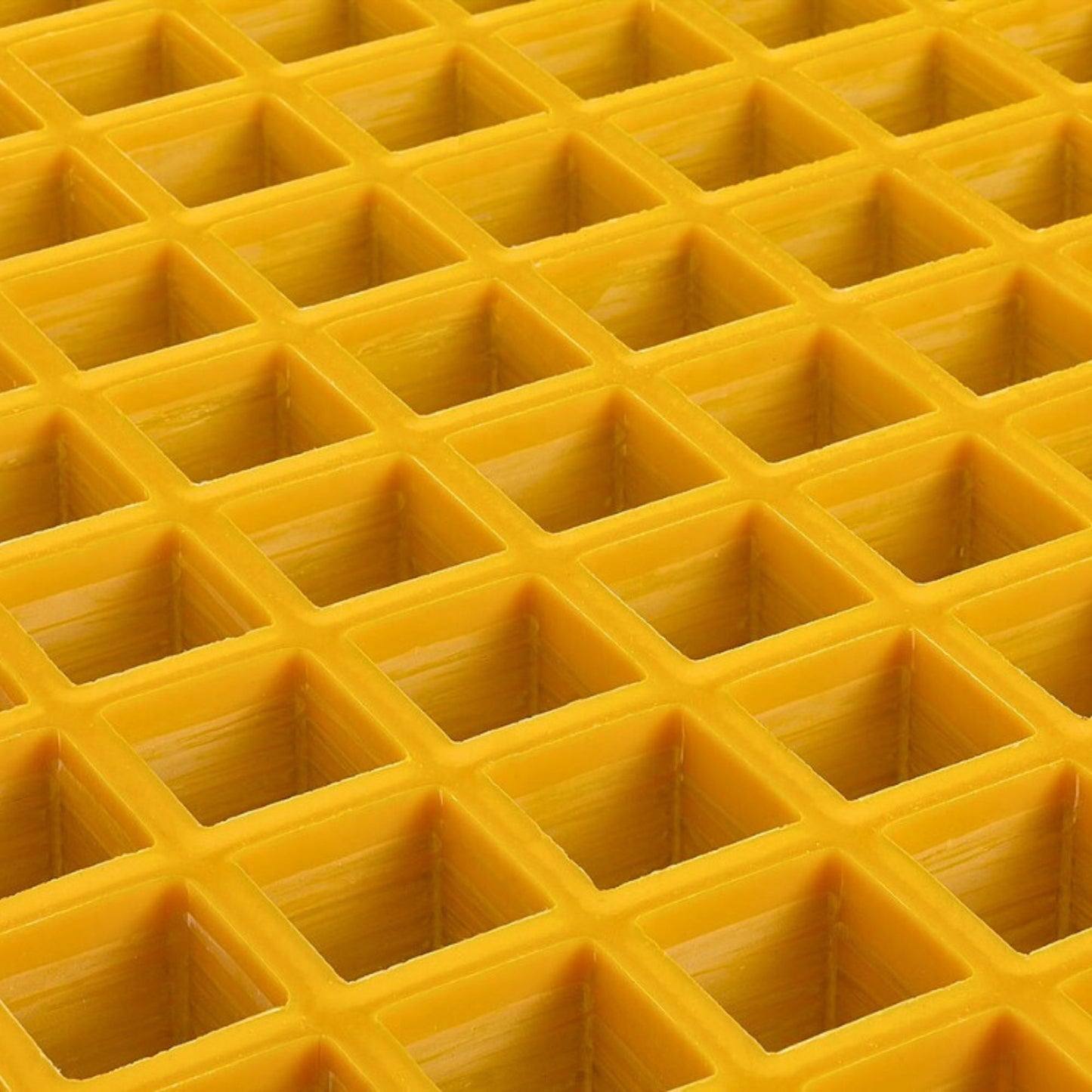

frp grating 25x25mm mini mesh

frp grating 25x25mm mini mesh

21 in stock

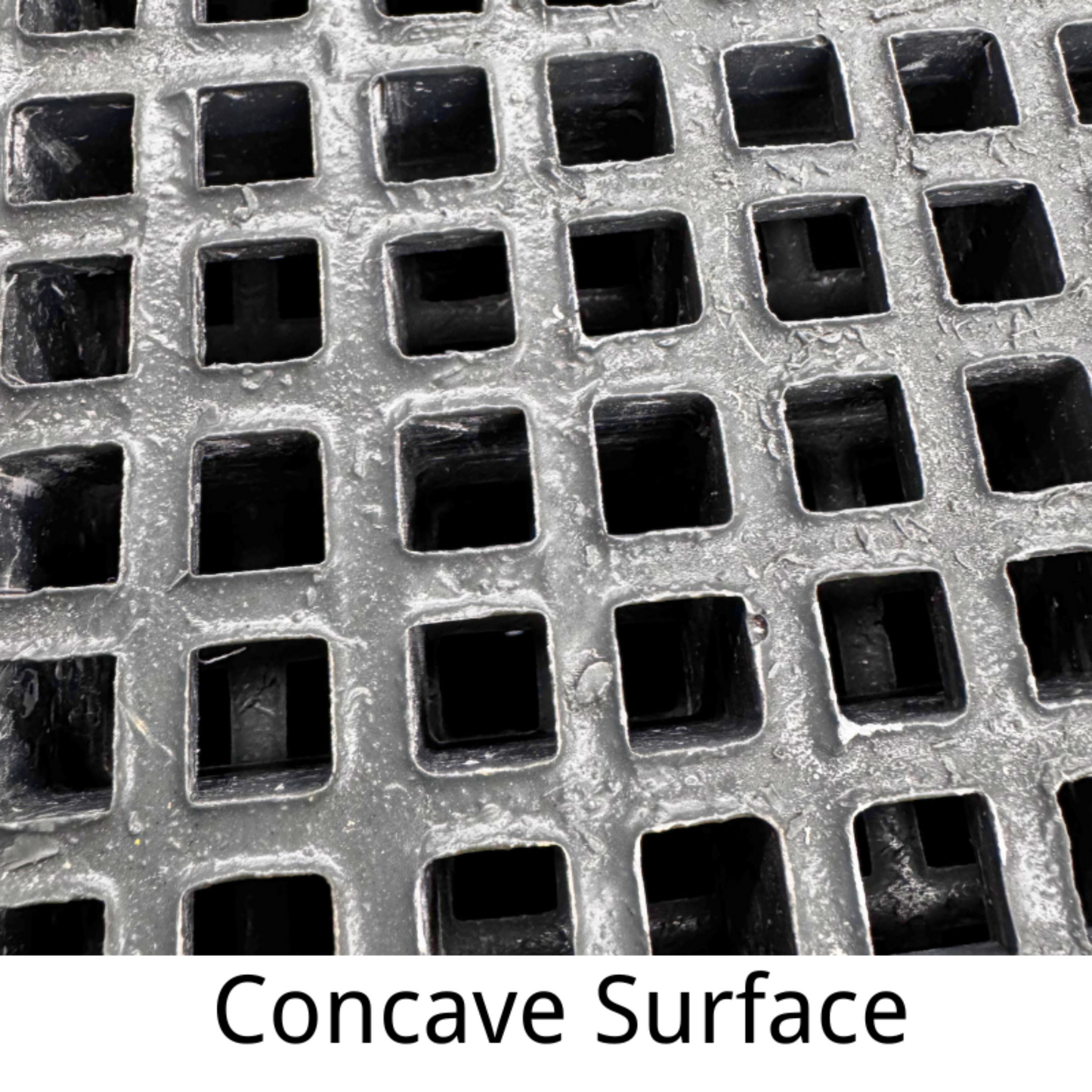

Concave Surface: 1220x2142mm, 1220x2189mm

A forklift is required for delivery if the panel exceeds 30 kg. Otherwise, the shipment will be sent to your nearest depot for collection.

Couldn't load pickup availability

Product Description:

The concave garting type is origin of the moulded gratings. During the heating of the gratings a concave surface is formed on the surface of the bars. This results in a very good slip-resistance. This grating achieve the serration class R13.

FRP-gratings with a concave surface are used in areas where good chemical and weather resistance is required.

Characteristics

- high corrosion and weather resistance

- high chemical resistance

- hygienic and resistant to bacteria

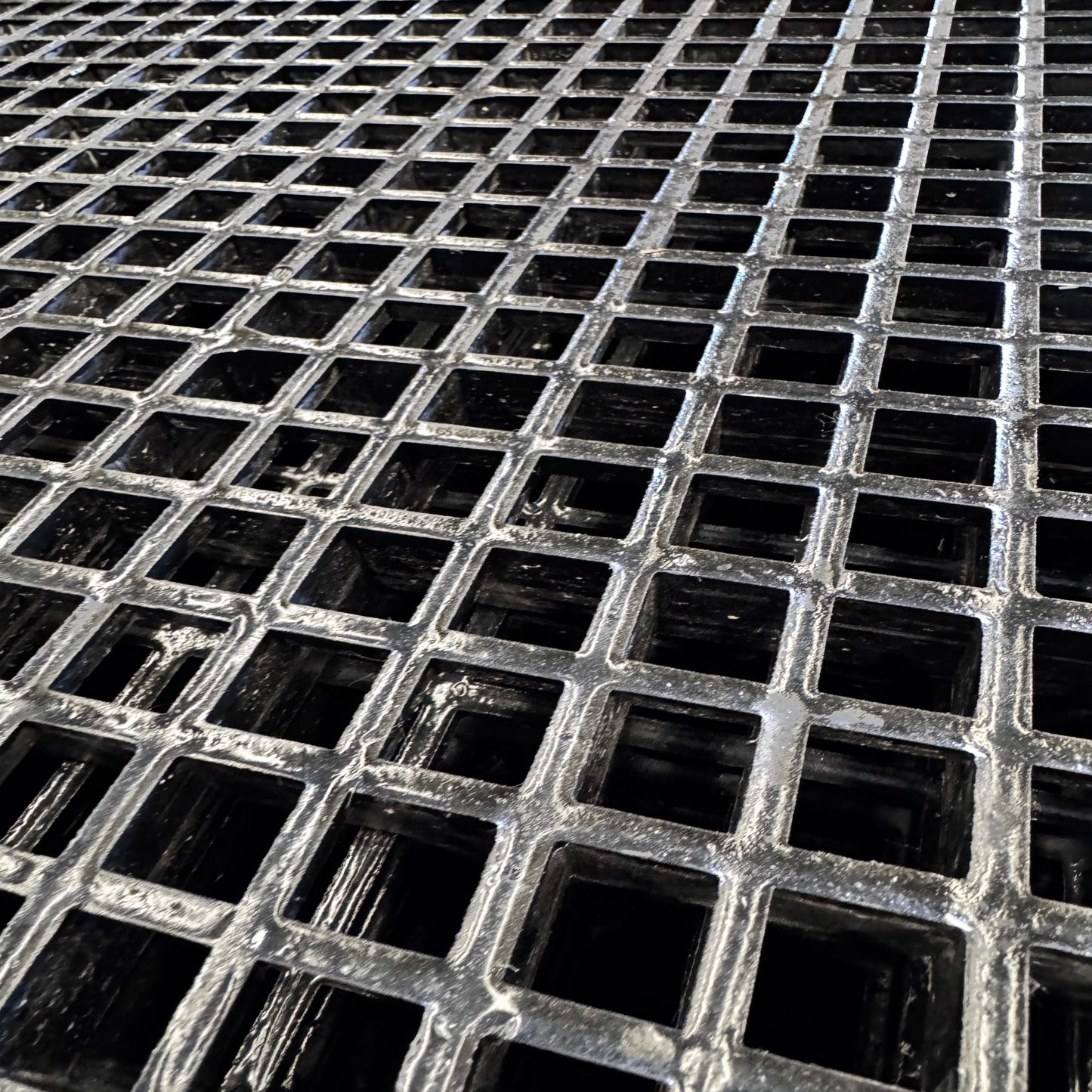

- the gratings are loadbearing in the direction of the supporting rods and the crossbars

- does not conduct electricity

- low thermal diffusivity

- Anti-slip up to R13

- relatively low dead weight

- simple and quick on-site assembly

- high levels of comfort for walking and standing

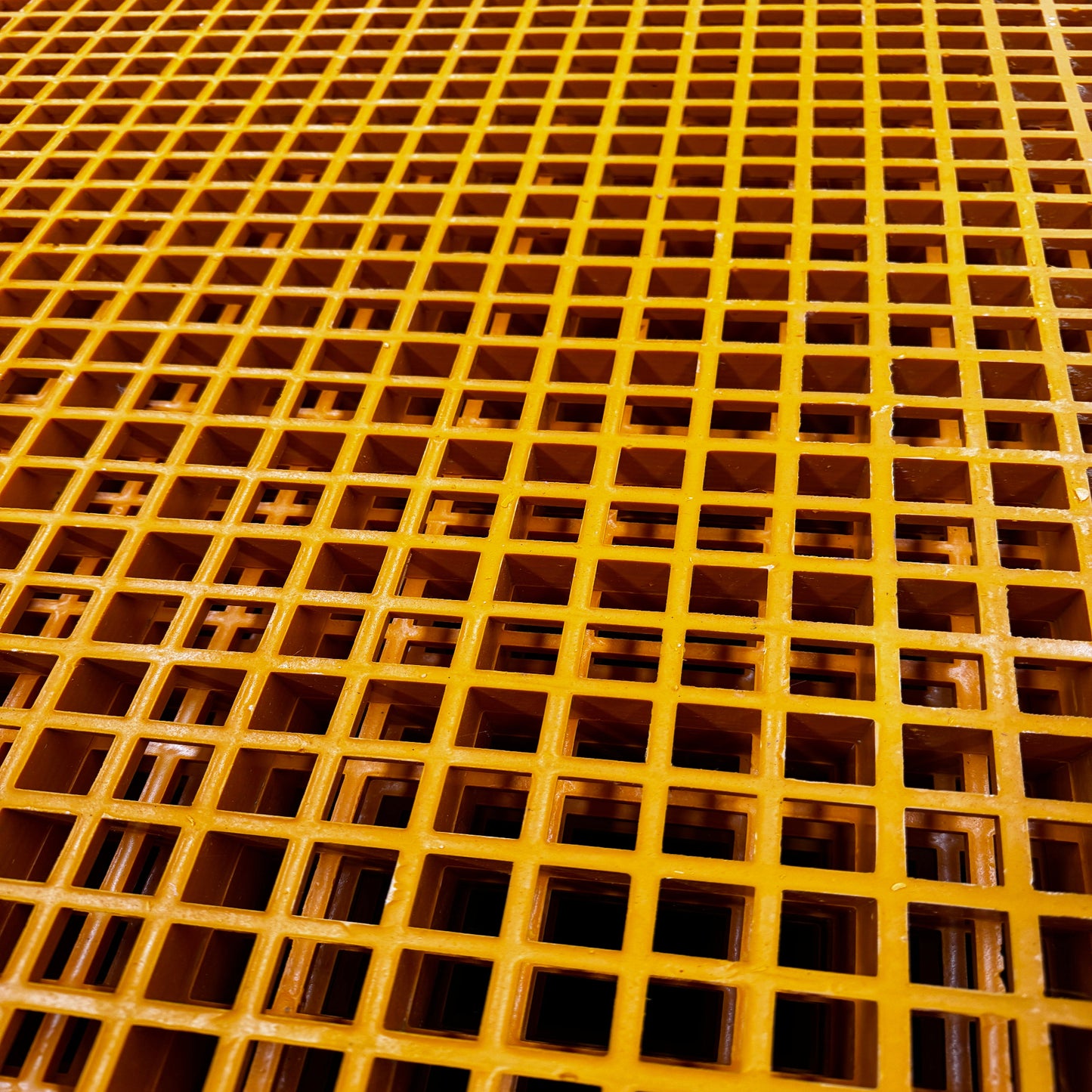

The gratings available from stock are manufactured on the basis of a high-quality isopthalic resin and are available in dark grey similar to RAL7015, Yellow RAL1023, Blue RAL5012, Green RAL6038 and Black RAL9011. Mesh Size is 25x25mm, the hole size is 19x19mm.

The chemical resistance of the grating is determined by the resin used. The following resin versions are possible:

- Orthophal resin:medium chemical resistance

- Isophtalic resin:good chemical resistance

- Vinylester resin:very good chemical resistance

How to lock down the grating? We have the fixing clips you may needed.

Main Applications of FRP Grating Mini Mesh 25x25mm:

- – Used in water treatment plants, trenches, and stormwater systems to allow flow while preventing debris buildup.

- – Ideal for light-duty industrial catwalks, mezzanines, and service areas where slip resistance is critical.

- – Acts as a support grid for filter media in wastewater plants, aquaculture, and chemical processing.

- – Used in HVAC systems, duct covers, and equipment enclosures for corrosion-free airflow.

- – Resists saltwater corrosion in docks, ship decks, and offshore platforms.

- – Safe for substations, switch rooms, and explosive environments (non-conductive, non-sparking).

- – Resists fertilizers, animal waste, and acidic washdowns in farms and food plants.

- – Used in architectural designs, sunshades, and façade cladding for a lightweight, durable finish.

Cut To Size

Whether you're working on a small DIY project or a commercial project, we're proud to offer cut-to-size sheets here in the heart of Melbourne.

We use the circular saw or grinder with diamond blade.

Frequently Asked Questions

Does FRP crack easily?

FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

What are the two main components of FRP?

FRP composite materials are usually based on two major components; fibers and polymer matrix. The stiffness and strength of composite materials are controlled by fibers, while the role of matrix is to transfer load and provide protection against environmental elements.

Is FRP bad for the Environment?

Plastic typically has a bad reputation when it comes to the environment and suffers from the image of cheap limitation, compared to other materials. But when used correctly, FRP is a good option that is much more sustainable than aluminium, steel or timber.

What is the life expectancy of FRP grating?

FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years.